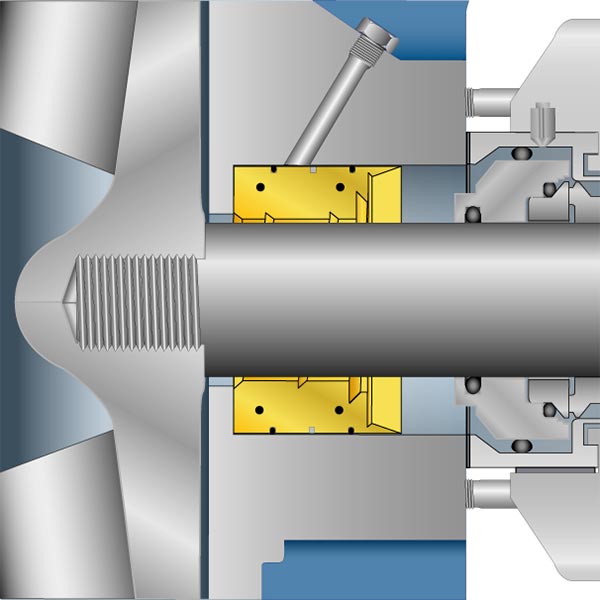

Used only with flush typically 5-8 gph (0.3 - 0.5 lpm). Version F is ideal for use with split mechanical seals. Since split devices are intended for installation with the pump in place, however, the pump cannot be modified to incorporate the air vent or exit groove extension required for flush free operation.

Slurry Pumps, Pulp n Paper, Municipal

No, these SpiralTracs are not designed to work with packing.

Typically, yes, providing there is enough room in the seal cavity for both the seal and SpiralTrac. In fact, SpiralTrac is an excellent and economical way of protecting your high cost double mechanical seals.

Typically, hard face seal combinations are used when erosive solids are present in the seal cavity. With SpiralTrac, however, solids are no longer present in the cavity. Since the seal is now operating in a cleaner environment, soft face seal combinations can be used at substantially reduced costs. Soft face seal combinations will also run cooler, further extending the mechanical seal’s life. Contact your seal manufacturer for recommendation.

The required flush pressure is dependent on the seal cavity pressure. Normal flush pressure should be above box pressure by a minimum of 1 Bar / 14.5 PSI, enabling the flush to push any contaminants under the existing throat.

These devices are split and designed to be easily installed in the field where the required upgrades associated with the air vent cannot be done. The use of flush also takes care of the air trapped in the seal cavity.

Yes. There are many installations where we are able to run flush free under the right conditions. After application details have been submitted and looked at, we can help you determine whether your application can run flush free with SpiralTrac.

The spiral groove always faces the seal and should spiral in the direction of the shaft as viewed from the seal end looking towards the impeller.

The part number is engraved on the impeller end of the SpiralTrac.

There is an installation label indicating the direction of rotation (which should be removed prior to installation).

If an air vent exists, it must be in the 12 o'clock position.

Double-ended pumps: There should be one left-hand rotation device and one right-hand rotation device. Direction of rotation is determined from the motor end looking towards the impeller.

Standard axial length of SpiralTrac Version F is 1.850"/47 mm. If a different length is required please contact us.

Yes! SpiralTrac can be designed to work with all mechanical seals.

Solution: seal

Application: Paper Stock

Equipment: Scanpump JMV double ended fan pump, Chesterton 442 Split Seal, Version F SpiralTrac

Solution: seal

Application: River Water

Equipment: Zillio Horizontal Francis Hydro Turbine, Chesterton 221 and 442 Split Seals, Version F SpiralTrac

Solution: seal

Application: Sodium Carbonate

Equipment: Goulds Elbow pumps, 221 and 442 Jumbo Split Seals, Version F Type S SpiralTrac