SpiralTrac™ is distributed worldwide, so wherever you are there's a distributor nearby. Use the form to search by country, or if you are looking for a specific company you can search by name as well. We can also help you locate the closest distributor in your region, send us a quick message and we'll get back to you shortly.

If you are a distributor and you aren't listed, please contact us so we can fix the issue. The information is correct to the best of our knowledge.

EnviroSeal has been in business for over thirty years, and in that time we learned a lot about the industry. Our applications engineers gained unmatched experience in sealing solutions, we have and keep providing support all over the World. The SpiralTrac technology is a very unique product and a definite game changer in the pump sealing industry. Just browse away in our library section among the incredible success stories we collected throughout the years. We know that our product makes a difference so we make each device count.

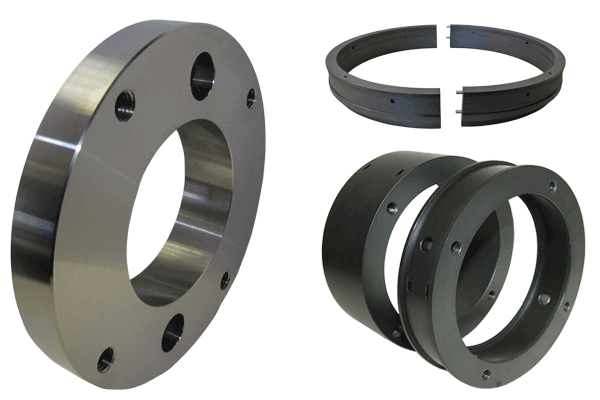

Our workflow starts with information gathering. A filled out order form can tell us most vital information we need to start production. Each order is evaluated by our engineers and we follow up right away if something seems out of place or unusual. However, an order form is not required. If you get in touch with us about an application, we can ask the right questions. Over the years we have come across countless challenges to know which direction to take, and of course new challenges are always welcome. And though most applications would benefit from the SpiralTrac geometry, if we feel like it wouldn't make a difference we will offer you solutions without SpiralTrac. Over the years customers have come to us with split bushing manufacturing requests, as they know at EnviroSeal they will find a solution. If we can manufacture what you need, we'll make it happen.

Once we have all the info we need, the design process begins. Using professional engineering software, once the design is finalized we can send a visual drawing upon request so you know exactly what you were getting.

We manufacture each device up to 14" diameter in house. Our skilled production staff works with the highest quality standards, and we make sure that each device is within spec. Certificate of compliance can also be requested at no additional cost.

So contact us, you can trust us with your sealing solution.

Get the information you need in the Literature section. You can find Brochures, Order Forms, Istallation Instructions, Success Stories and more.

Browse LiteratureNo, SpiralTrac is designed to operate in a fluid only.

SpiralTrac should not be used in any application where the process is at or near vapor margin. In this situation, any increase in temperature or decrease in pressure could cause flashing. Depending on the process, SpiralTrac may slightly change this condition, and we don't recommend taking the risk.

No, the SpiralTrac does not rotate. SpiralTrac's patented design creates new and unique flow patterns from existing flows caused by shaft and sealing element rotation.

No, since SpiralTrac does not contact the shaft/sleeve.

There should be one left-hand rotation (CCW) device and one right-hand rotation (CW) device (either packing or seal versions) utilized in a double-ended pump.

The maximum process temperature we recommend is 250ºF/120ºC. If your process temperature is higher than this, you should consider using a metal SpiralTrac. For additional material details visit enviroseal.ca/spiraltrac/material.

Typically, no. SpiralTrac cannot be used for most latex compounds or latex based paint because the exit groove would be filled by the material, and the functionality of the SpiralTrac would be degraded as a result.

The radial clearance between the shaft and inside diameter of the SpiralTrac is 0.020”-0.040”. Upon flooding of the pump, contaminants larger than this size cannot enter the seal cavity. Contaminants this size or smaller that do enter the seal cavity are easily removed by SpiralTrac. Should a larger piece of contaminant enter a seal cavity through the flush port, the SpiralTrac will attempt to remove it. If there is a throat at the end of the seal cavity the largest contaminant is dictated by the throat clearance.

EnviroSeal offers SpiralTrac in a number of materials: ESC (carbon-graphite filled PTFE), GLF (glass-filled PTFE), 416 & 316 stainless steel, bronze, and titanium. The material selection depends on the application and is normally made by the customer to fit the required needs. Often, the SpiralTrac is constructed of the same material as the pump, and since it is a machined product, it can be made from just about any machineable material. Consult EnviroSeal to determine which is best suited for your application.

Email us at support@enviroseal.ca, our technical support team can help you figure out whether SpiralTrac would be beneficial to your application.

Direction of rotation is determined from the motor end looking towards the impeller.

EnviroSeal offers SpiralTrac in a number of standard materials. For details on these materials please visit our website at enviroseal.ca/spiraltrac/material. However, we can manufacture SpiralTrac from any machinable material, let us know your specific needs and we’ll do our best to accommodate your request.

Material selection depends on the application and many other factors. Based on the application information provided to us we will always make sure you use the appropriate material.

In order to get a quote, fill out as much information as you can on one of our SpiralTrac Quote Forms and email it to us.

We offer SpiralTrac through A. W. Chesterton’s Worldwide distribution network. Find your country in our Distributor Locator or email us with your location (address and zip code) and we’ll put you in touch with your local authorized distributor.

Some SpiralTracs are designed to be easily installed on site without the use of any tool, some designed with a press fit and requires the equipment to be disassembled. Refer product installation instruction for details.

Any equipment that has a stuffing box/seal chamber. Horizontally or vertically mounted centrifugal pumps, agitators, vertical turbines, refiners, hydro turbines, etc.

Highly dependant on application, but typically you can expect a reduction of 60%-80% flush rate needed for successful operation. Please note, SpiralTrac does not reduce flush on its own, it allows the application to run successfully with a reduced flush rate! EnviroSeal always recommends the use of flow controller and check valve when installing SpiralTrac.

This room is dependant on the distance of your first obstruction. If this distance is shorter than the SpiralTrac needed we may be able to manufacture SpiralTrac in multiple axial pieces.

Typically, no, you will need less rings of packing after installing SpiralTrac. For example, in the commonly used 2L3 setup SpiralTrac replaces the bottom 2 rings of packing and the lantern ring so instead of 5, you will only need 3 rings of packing.

No, our standard Packing Version SpiralTrac reduces the amount of flush needed to run the application successfully. To achieve flush reduction EnviroSeal recommends the use of flow controller and check valve.

Yes. SpiralTrac is designed to replace any packing-lantern ring configurations.

Typically, No. The SpiralTrac is designed to inserted from the gland side of the stuffing box with a locational clearance fit. The rings of packing and the gland follower keeps the device in place.

No. However, if you are changing the packing and time is available, you can remove, inspect, clean and reinsert the SpiralTrac before replacing the packing. When inspecting the device make sure there is no obstruction in the spiral and the flush holes.

Yes. We recommend choosing your packing based on operating conditions. All packing should be broken in according to manufacturer specifications.

There are a number of methods to ensure the SpiralTrac Version P is installed correctly:

There is an installation label indicating the impeller side of the device (which should be removed prior to installation).

Rotation direction is engraved on the lantern ring section.

The part number is engraved on the impeller end of the SpiralTrac.

The tangential hole will inject the flush in the direction of shaft rotation.

The puller holes that facilitate the removal of the device should be facing the gland.

Typically, we recommend a minimum of 3 rings of packing above the SpiralTrac. However many times, mostly in low pressure applications, we have successfully used SpiralTrac with only 2 rings of packing.

MGE (PPS blend thermoplastic), BGE (PEEK blend thermoplastic) and 660 Bronze.

Yes. As this is still a packed application, the gland follower would be tightened just beyond finger tight. Adjustments are still going to be necessary however they should be less and fewer in between. We often come across applications where 6 or more months go by in between adjustments.

The required flush pressure is dependent on the stuffing box pressure. Normal flush pressure should be above box pressure by a minimum of 1 Bar / 14.5 PSI, enabling the flush to push any contaminants under the existing throat.

Depends on where the sleeve is worn. SpiralTrac can function properly over a worn sleeve. It is very important that the sleeve area under the packing outboard of the SpiralTrac is in good condition.

The minimum axial length of Packing Version SpiralTrac is 1”/25.4 mm.

These devices are designed to be easily installed in the field where the required upgrades associated with the air vent cannot be done. The use of flush also takes care of the air trapped in the stuffing box.

The Packing Version SpiralTrac typically has puller holes on the gland side of the device to facilitate the starting of a packing extractor. For more information please refer to the installation instruction.

Yes, both split and non-split Packing Version SpiralTracs are available in metal.

No. All Packing Version SpiralTracs require flush to force the contaminants under the existing throat.

They differ in the length of the devices and the applications that they are used in:

Version N typically used in non-fibrous applications (silt, sand)

Version D typically used in fibrous applications (pulp, corn mash, wastewater)

Version C typically used in intermittent services (product crystallizes, hardened when cooled)

No, these SpiralTracs are not designed to work with packing.

Typically, yes, providing there is enough room in the seal cavity for both the seal and SpiralTrac. In fact, SpiralTrac is an excellent and economical way of protecting your high cost double mechanical seals.

Typically, hard face seal combinations are used when erosive solids are present in the seal cavity. With SpiralTrac, however, solids are no longer present in the cavity. Since the seal is now operating in a cleaner environment, soft face seal combinations can be used at substantially reduced costs. Soft face seal combinations will also run cooler, further extending the mechanical seal’s life. Contact your seal manufacturer for recommendation.

Yes. There are many installations where we are able to run flush free under the right conditions. After application details have been submitted and looked at, we can help you determine whether your application can run flush free with SpiralTrac.

The spiral groove always faces the seal and should spiral in the direction of the shaft as viewed from the seal end looking towards the impeller.

The part number is engraved on the impeller end of the SpiralTrac.

There is an installation label indicating the direction of rotation (which should be removed prior to installation).

If an air vent exists, it must be in the 12 o'clock position.

Double-ended pumps: There should be one left-hand rotation device and one right-hand rotation device. Direction of rotation is determined from the motor end looking towards the impeller.

The typical clearance between the SpiralTrac and the OD of the shaft is 0.018" / 0.46mm radial, but this can vary depending on the size of the device and the material it is made from.

Yes! SpiralTrac can be designed to work with all mechanical seals.

No, these SpiralTracs are not designed to work with packing.

Typically, yes, providing there is enough room in the seal cavity for both the seal and SpiralTrac. In fact, SpiralTrac is an excellent and economical way of protecting your high cost double mechanical seals.

Typically, hard face seal combinations are used when erosive solids are present in the seal cavity. With SpiralTrac, however, solids are no longer present in the cavity. Since the seal is now operating in a cleaner environment, soft face seal combinations can be used at substantially reduced costs. Soft face seal combinations will also run cooler, further extending the mechanical seal’s life. Contact your seal manufacturer for recommendation.

The required flush pressure is dependent on the seal cavity pressure. Normal flush pressure should be above box pressure by a minimum of 1 Bar / 14.5 PSI, enabling the flush to push any contaminants under the existing throat.

These devices are split and designed to be easily installed in the field where the required upgrades associated with the air vent cannot be done. The use of flush also takes care of the air trapped in the seal cavity.

Yes. There are many installations where we are able to run flush free under the right conditions. After application details have been submitted and looked at, we can help you determine whether your application can run flush free with SpiralTrac.

The spiral groove always faces the seal and should spiral in the direction of the shaft as viewed from the seal end looking towards the impeller.

The part number is engraved on the impeller end of the SpiralTrac.

There is an installation label indicating the direction of rotation (which should be removed prior to installation).

If an air vent exists, it must be in the 12 o'clock position.

Double-ended pumps: There should be one left-hand rotation device and one right-hand rotation device. Direction of rotation is determined from the motor end looking towards the impeller.

Standard axial length of SpiralTrac Version F is 1.850"/47 mm. If a different length is required please contact us.

Yes! SpiralTrac can be designed to work with all mechanical seals.

The split device made of ESC material has been pressure tested to 100 PSI / 6.9 Bar. The typical applications for the Adaptor are well within this limit. Should you have a higher-pressure application and still require a split device, contact EnviroSeal.

The two halves are machined to a smooth finish to ensure total face contact when tightened together with the socket-head cap screws that are supplied with each device. Split metal Adaptors are supplied with a gasket sealant which should be applied for each half. Refer to installation instruction for details.

No, these SpiralTracs are not designed to work with packing.

The turbulence in the seal cavity will not be changed with the standard Adaptor. What is important is to protect the environment around the seal itself, and that is achieved with this design. An option, should you wish to control the turbulence in the seal cavity, is to order the Adaptor with a nose piece that will fill the entire void of the seal cavity. It is important to note that this option can be used only when there is enough first obstruction space available.

Typically, hard face seal combinations are used when erosive solids are present in the seal cavity. With SpiralTrac, however, solids are no longer present in the cavity. Since the seal is now operating in a cleaner environment, soft face seal combinations can be used at substantially reduced costs. Soft face seal combinations will also run cooler, further extending the mechanical seal’s life. Contact your seal manufacturer for recommendation.

No. We recommend to use flush with all SpiralTrac Adaptors.

SpiralTrac Adaptor can be your answer when:

Split SpiralTrac Adaptors are available in ESC and metal.

Composite Adaptors have a built-in gasket. For metal Adaptors customer must supply their own gasketing material.

Yes. Packing SpiralTrac Adaptors are typically used to help large equipment keep running until the worn shaft/sleeve can be replaced

Have a question about an application? Need some clarification on SpiralTrac versions or help picking the best material? Our engineering team is here for you. Fill out the form and we can guarantee to get back to you within 24 hours.

You may also call us at +1 (902) 861-3464 Monday - Friday 8 AM - 4:30 PM (ADT).