Similar to the version N, but with an integral bottom drain that allows process to drain from the seal cavity on pump shutdown, minimizing process crystallization problems on pump restart and increasing maintenance safety.

chemical processing

They differ in the length of the devices and the applications that they are used in:

Version N typically used in non-fibrous applications (silt, sand)

Version D typically used in fibrous applications (pulp, corn mash, wastewater)

Version C typically used in intermittent services (product crystallizes, hardened when cooled)

No, these SpiralTracs are not designed to work with packing.

Typically, yes, providing there is enough room in the seal cavity for both the seal and SpiralTrac. In fact, SpiralTrac is an excellent and economical way of protecting your high cost double mechanical seals.

Typically, hard face seal combinations are used when erosive solids are present in the seal cavity. With SpiralTrac, however, solids are no longer present in the cavity. Since the seal is now operating in a cleaner environment, soft face seal combinations can be used at substantially reduced costs. Soft face seal combinations will also run cooler, further extending the mechanical seal’s life. Contact your seal manufacturer for recommendation.

Yes. There are many installations where we are able to run flush free under the right conditions. After application details have been submitted and looked at, we can help you determine whether your application can run flush free with SpiralTrac.

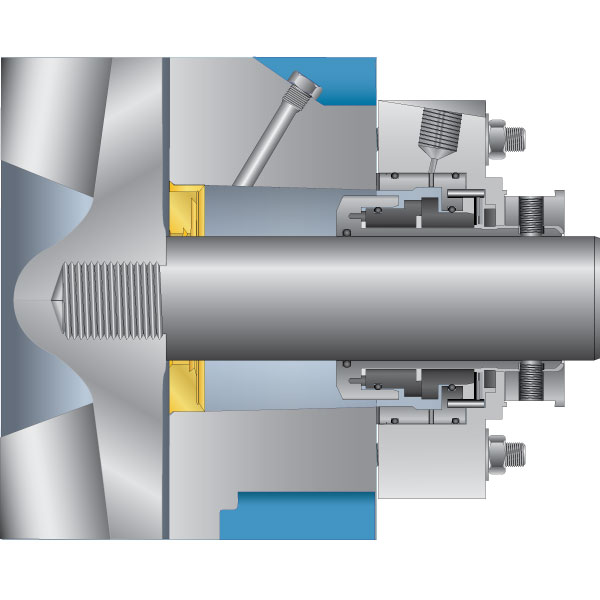

The spiral groove always faces the seal and should spiral in the direction of the shaft as viewed from the seal end looking towards the impeller.

The part number is engraved on the impeller end of the SpiralTrac.

There is an installation label indicating the direction of rotation (which should be removed prior to installation).

If an air vent exists, it must be in the 12 o'clock position.

Double-ended pumps: There should be one left-hand rotation device and one right-hand rotation device. Direction of rotation is determined from the motor end looking towards the impeller.

The typical clearance between the SpiralTrac and the OD of the shaft is 0.018" / 0.46mm radial, but this can vary depending on the size of the device and the material it is made from.

Yes! SpiralTrac can be designed to work with all mechanical seals.

Solution: seal

Application: Sulfuric Acid

Equipment: Worthington 2.5M 182 Slurry Pump, Chesterton S10 Cassette Seal, Version C SpiralTrac

Solution: seal

Application: Chemical Waste Water

Equipment: Allis Chalmers pump

Solution: seal

Application: Black Liquor

Equipment: ABS Scanpump