94% Flush Reduction with the Chesterton SuperSet™ Total Sealing Solution

- November 30, 2020

- 6.1 Thousand

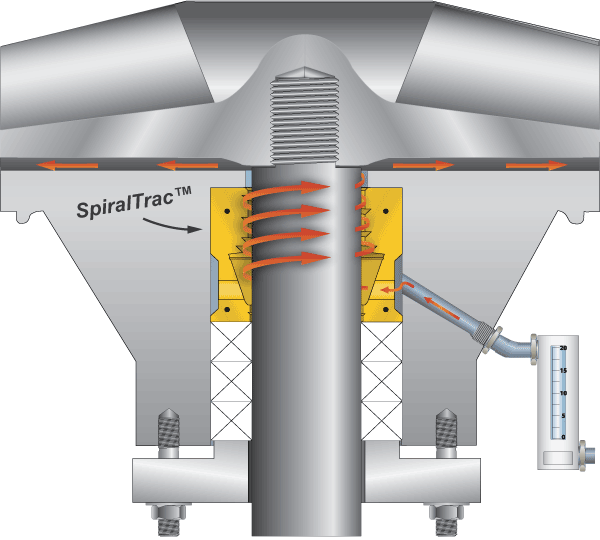

Packing Version SpiralTrac and three rings of Chesterton 370 Heat Dissipating Packing helps reduce flush water usage in a Vertical Hydropulper.

Application Info & Challenge

- Vertical Hydropulper, sleeve diameter: 150 mm, shaft rotation: 360 RPM

- Product: Paper stock, ambient temperature

Typical 2L3 packing configuration with competitor “low cost“ PTFE/Graphite packing. Stainless steal shaft sleeve with ceramic coating.

Customer ran into issues with short packing life of 4-5 weeks and short sleeve life of about 8 weeks.

Excessive measured flush water usage at 32.6 l/min! Leakage problems: water spraying out at the gland follower, causing massive environmental and safety issues.

Leakage problems with original sealing setup

Flow monitor reading 32.62 l/min flush water usage

Solution & Results

- Chesterton Superset: 3 rings of 370 Heat Dissipating Packing, and Packing Version SpiralTrac™ made of Carbon Graphite PTFE (ESC) material.

- Chesterton S50 Flow Guardian™ flow meter.

After installation of the SuperSet, the results were immediate and profound. Packing MTBR went from 4-5 weeks to 9 months! That is already a huge savings in production and maintenance resources as the pump didn't have to be shut down for repacking purposes.

Flush water reduced to 3 l/min. That is a (spoiler alert) 94% reduction in water usage alone! To put this number into perspective, assuming the pulper is running continuously, that is 42,624 liter water saved on this one hydropulper alone in one day! In a run of a year that is over 15 million liter water saved, which would fill about 6 olympic sized swimming pools. Impressive!

Since the SpiralTrac is not a tight clearance bushing, it does not restrict flow automatically. What it does however, it allows the application to run successfully with less amount of flush water utilized. In most cases, a lot less! EnviroSeal always recommends flow controls when installing a Packing Version SpiralTrac, so the amount of flush water entering the stuffing box can be precisely monitored. We also recommend the installation of a check valve on the flush line to prevent any back flow in case the flush pressure drops below stuffing box pressure for any reason.

The ROI time frame on this pump was 1 month! Old operating cost: €43,174, current operating cost: €3.343

That is a 92.2% reduction in operating cost!

For more information please reach out to us at support@enviroseal.ca. We hope to hear from you!

Download this Application Highlight as a PDF