SpiralTrac™ Packing Version Benefits

- January 17, 2017

- 7.41 Thousand

For years SpiralTrac technology has been blazing trails for customers who use mechanical packing, allowing them to gain outstanding features and important benefits not available previously.

In conjunction with high quality packing, customers are afforded a unique sealing solution for any application, while also being provided the opportunity to dramatically reduce direct and indirect costs associated with the operation of packed pumps and equipment. Some of these benefits are:

Flush can be reduced by 60% or more in many applications with the use of a flow controller

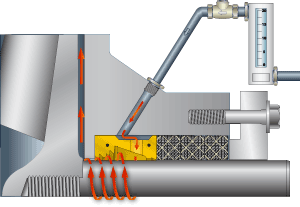

Through the use of tangential injection into a centrifugal separation chamber, and the incorporation of spiral grooving, SpiralTrac Version P is able to use flush far more effectively and efficiently in rejecting particulate from the pumpage. This permits the flush rate to be metered to much lower, and known quantities. This can dramatically benefit most process and effluent cost considerations.

Less leakage

The packing used with SpiralTrac Version P must be of a high quality that will enable control of leakage to a drip rate. This results in a far cleaner working environment, longer bearing service life, and reduced housekeeping costs.

The packing set is less sensitive to dirt in the flush water

In most mill and mining services, the flush itself contains solids from pipe scale, silt or from settling ponds. Current approaches use a lantern ring between two sets of packing. The dirt is injected with the flush and forced under one or both sets of packing, contaminating the inner surface and scoring the shaft in the process. SpiralTrac Version P collects this dirt and channels it from the chamber through a dedicated exit groove.

Greatly reduced sleeve wear

Dirt from flush is rejected instead of imbedding in the packing. As well, most of the dirt attempting to enter the packing set from process is captured in the spiral grooving system and rejected with the flush before it can embed under the packing rings above the SpiralTrac. The combination has proven to dramatically reduce sleeve wear, and in turn make the sealing system less sensitive to axial and radial movement.

Left image: Sleeve wear in a regular 2L3 packing configuration, Right image: same application sleeve condition after 2 years run time!

Longer packing life

Previously, the lowest grade of packing was used in many applications since the service was so rugged or difficult that good packing simply tore out as quickly, as lower grades. SpiralTrac Version P finally enables the economic use of high-grade packing, enabling users to gain the advantages of their inherent ability to operate longer, with less leakage, and less sleeve wear.

Cleaner Leakage

One of the most frequent reports from the field is the comment that the leakage from the packing set is not only reduced to drip rate, but that the contaminant level within the leakage is astonishingly low. This has been especially the case in stock applications on the larger shaft installations such as refiners and hydropulpers. This again translates to massive visual and house cleaning benefits to the user.

The proven solution to packing large rotating equipment

SpiralTrac Version P has provided a long-awaited answer to the problems associated with packing and maintenance of not only pumps and mixers, but for large rotating equipment where the benefits have been even more evident. This equipment has included agitators, refiners, hydropulpers, and thick stock pumps. These pieces of equipment were previously known for the difficulties associated with controlling and maintaining low leakage conditions.